| Location:Home > Multilayer Circuit PCB > WIFI module half hole PCB |

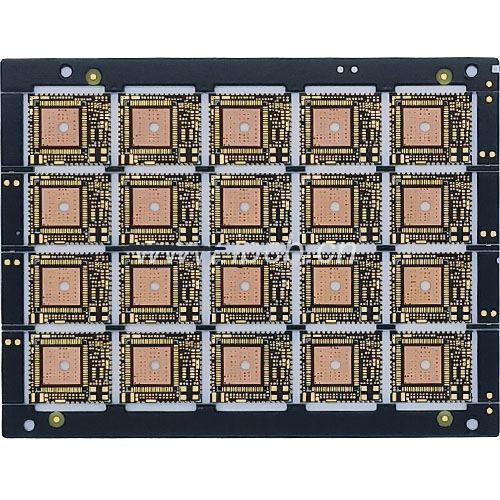

WIFI module half hole PCBProduct type:WIFI module half hole PCBMaterial:FR4 material (Shengyi S1000-2) Layers/plate thickness:4-layer through hole board Surface treatment:Chemical Immersion Gold + OSP Antioxidant Line width/line spacing:0.075mm(3mil)/0.075mm(3mil) Applications:WIFI Module Contact Us |

At present, the mainstream networking methods of the Internet of Things include various embedded modules such as WiFi, Bluetooth, GPRS, GPS, LoRa, and 2.4G.

The conventional requirement for the half hole diameter of the PCB circuit is 0.6MM-0.5MM, 0.5MM-0.4MM is difficult, and the conventional circuit board layers are 2-12 layers.

The module circuit board with high integration needs to use the HDI second-order or any-order structure, and the minimum line width/line spacing is 3mil/3mil or local 2.5mil/2.5mil.

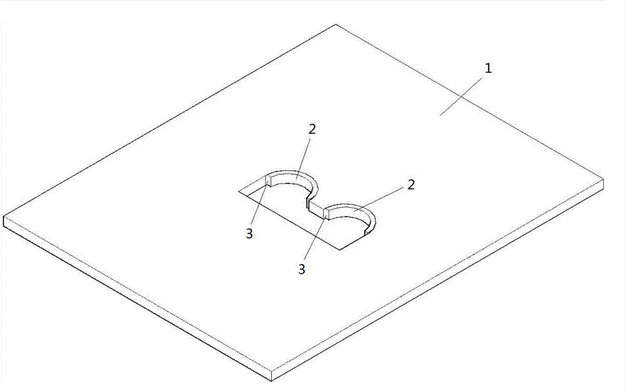

A WIFI module metallized half-hole PCB board, comprising metallized half-holes, edges of the metallized half-holes are provided with etching grooves, the etching grooves are rectangular parallelepiped grooves, and the edge lines of the metallized half-holes are The distance between the metallized half hole and the diameter parallel to the edge line is 0.1±0.02 mm, and the etching groove runs through the entire PCB along the thickness direction of the PCB.

Preferably, the metallized half hole is formed by die punching of the metallized circular hole before forming, and the metallized circular hole is etched with an etching groove on both sides of the center line of the die punch, and the etching groove is along the thickness direction of the PCB board. Throughout the entire PCB board, the distance between one edge line in the length direction of the etching groove and the center line of the die punch is 0.1 ± 0.02 mm, and the other edge line coincides with the center line of the die punch.

Preferably, the distance between the edge in the width direction of the etching groove and the diameter of the metallized half-hole parallel to the edge is not less than the radius of the metallized half-hole.

Compared with the prior art, the advantages of the present invention are: the edge of the metallized half-hole of the present invention is provided with an etching groove, the etching groove is etched before the metallized half-hole is formed, and then the metallized half-hole is formed by die punching. Half-hole, metallized half-hole has a smooth surface, and there is no drape residue, so there is no need to increase the post-processing process of the drape, which improves the quality of the product and improves the production efficiency.